Springs are essential for many industries, including energy, oil and gas, automobile, and mechanical industries.

If you are working on one of these, it’s best to be well-versed with the springs available in the Texan market. Plus, you also have to know where they are applied. By doing so, it can lessen errors that could ultimately cost you.

That said, here are some of the most common types of springs and their application.

Torsion Springs

Torsion springs are helical or spiral springs that exert rotational force, which is known as torque. The ends of these springs typically rotate around a rod or the central axis to work. These springs are winded up by the load.

You can buy customized torsion springs in Texas based on its application. There are straight torsion arms along with hinged and hook designs that could suit different applications.

It’s even possible to get them in any shape with precision tolerances for your project.

You’ll commonly see torsion springs on everyday objects like a mousetrap, clocks, and watches, or a clothespin. But, they are also present in circuit breaker mechanisms and automatic machinery.

Compression Springs

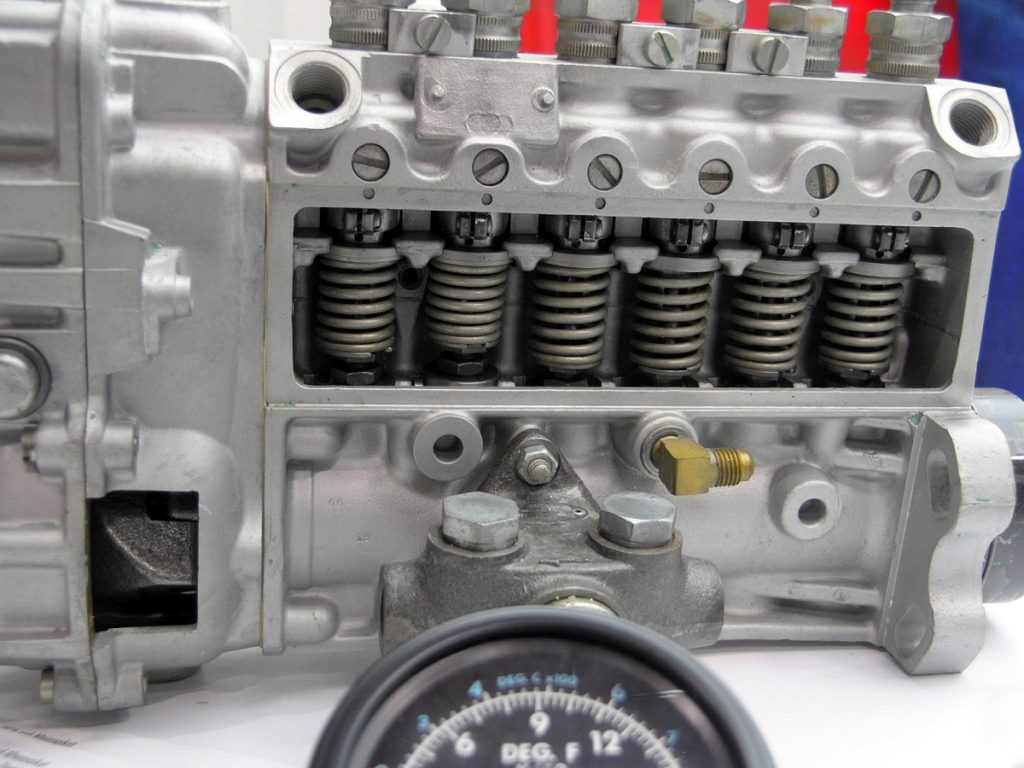

Compression springs are helical springs that resist an applied force when compressed. It also stores energy during pushed configurations. As the load increases, the spaces between the coils close until they touch each other, which signifies the maximum load they can take.

There are various sizes of compression springs based on where they are applied. Nevertheless, they are usually made for manufacturing applications.

As with torsion springs, they can also be customized to best suit your project. They can be made from various metal alloy materials.

Compression springs are one of the most common springs you’ll find around you. It’s in mattresses, retractable pens, mechanical pencils, shock absorbers, and more.

Extension Springs

Extension springs are another helically coiled springs that work with a tensile load. That means it provides an opposing force when it is stretched. In some ways, there is quite the opposite of compression springs. If it’s harder to understand extension springs, the Slinky is an excellent comparison to it.

There are several applications for this spring, especially in manufacturing applications. With that, extension springs come in different sizes, dimensions, and can be made from a variety of materials.

You commonly find extension springs in garage door mechanisms.

Other Types of Springs

There are other types of springs you can find, including:

- Belleville springs – These are also known as disc springs because of their appearance. Professionals typically use these springs with fasteners, like bolts.

- Constant force spring – This spring resembles a roll of tape. It contracts when the force is applied, but it rebounds with a continuous force once it is released. You’ll see this spring in wind-up toys.

- Leaf springs – These springs have metal plates of varying lengths. The plates are then held together by bolts and clamps. You can see leaf springs on suspensions for cars.

Springs may be small, but they are an important part of different everyday objects we use. Without them, these items can’t function properly. That said, you also need to know which type is used for which.